There are three main things you need to focus on when buying a laser cutter. These are functionality, accessibility, and reliability. A good system strikes a balance between these three key elements. In order to know that you have a good design in front of you and all of the above, you have to really observe the devices.

You can do this in a variety of ways because the truth lies in the information that any salesperson can give you. For example, the system that should suit you will meet your requirements such as power, speed, laser marking, but much more than that. So do not buy less or more than what you need, and you will achieve that with a few of our tips.

-

Application

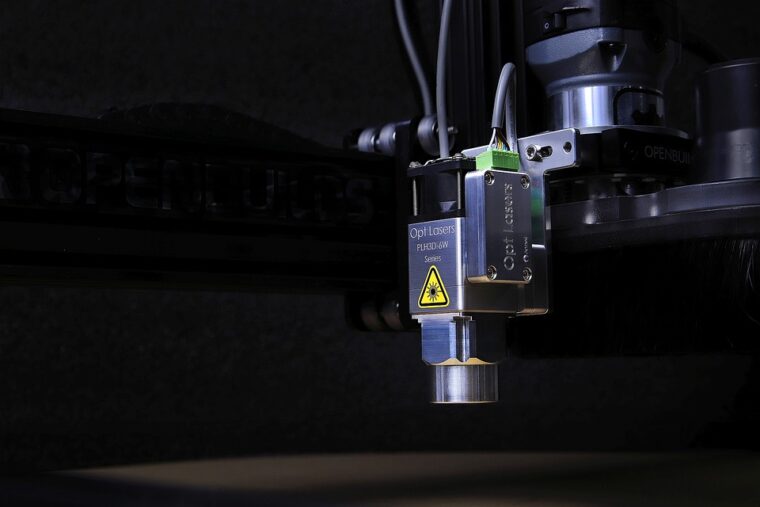

In the first place is the basic application of lasers. So, you need to consider whether you need laser engraving or laser cutting. It is important to determine this first, and only then the other applications. Remember that a good machine meets all the requirements you have when it comes to business. For example, if the machine cuts and engraves at the same time, it does not mean that it is the best choice for you. Maybe one function is much better than the other, and maybe both are pretty bad. However, a machine that performs only one function will do much better than one that performs more.

-

Machine potential

This means you need to know throughput or the number of parts it produces per hour. Your job largely depends on this and you must not forget it. For example, if you currently have a small workload, we are sure you want to increase it. If you opt for a machine that produces few parts, you will not progress. On the other hand, higher traffic will allow you the commercial success you are striving for. This way you will lower your sale price but also increase your margin. In that case, you will deliver much faster. When it comes to fighting competition, you need to know how to stand in their way. You will succeed if you do as much work as possible and develop your laser engraving business.

-

Costs

The price of the machine is important, but we must not forget about maintenance costs. Our advice is to consider it a priority in this situation because there is a low price trap. For example, many dealers will offer you a machine for very low prices, which you will really like. However, do not agree to this if the maintenance costs are much higher than you thought. It is not profitable, and the working life of the average machine is about 10 years. Use this number and calculate whether it pays to buy a certain machine.

-

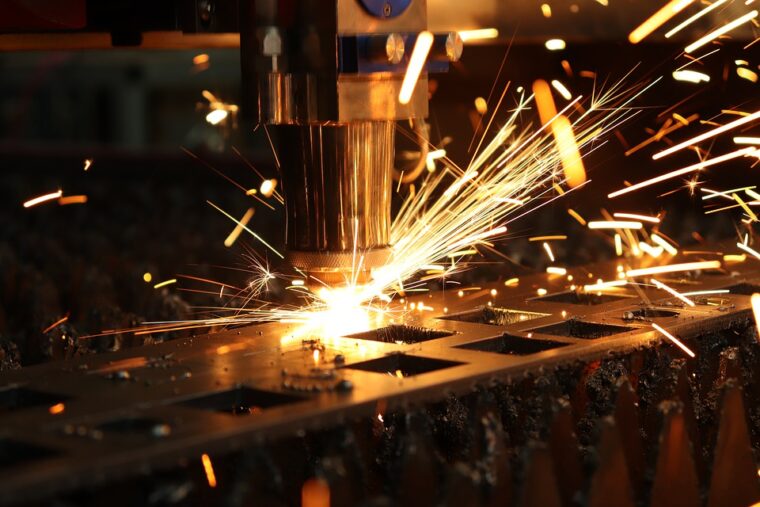

Potential replacement of parts

You have to be very careful when buying used machines. With them, you just never know what you’re up to unless you don’t have all the information with you. The person you work with is required to provide you with all information about them such as the period of use, brand, purchase invoices and other things. Just like when buying a car, the operating history of the device you are buying is important. Since these machines are not cheap, they should serve you for many years. Also some are very complex, like fiber laser cutting system you can check at www.dxtech.com so you shouldn’t take any risk. However, you can’t work with worn or damaged parts, so think about it at the very beginning. Think about how much its spare parts cost, whether they are easily available or you will have to wait a long time before you get them.

-

Specifications

Put the brand in second place when it comes to choosing a machine while specifications should be the primary thing. Buyers often decide to buy items with a well-known brand behind them, and that is a normal occurrence. Well-known brands have loyal customers who are satisfied with their service, but even a brand you are loyal to can make a mistake or have nothing for you. So don’t just be guided by it but look at the bigger picture of the market.

There are also small brands that are still in development and can offer excellent quality and a machine that fully meets your requirements. All you have to do is research what is on the market and compare some performance technologies with your needs. We are sure you will find a lot of models that are compatible with them. Sometimes smaller brands can surprise you with some innovations you haven’t seen before and had a chance to try. You can also save a fortune this way.

-

Warranty

No matter how good the machine may seem, manufacturing mistakes happen to the best. Also, nothing lasts forever, every machine will eventually break down and you can’t do anything about it. What you need to do is insure yourself in case it cancels prematurely. This way, you will not throw money at a machine that will break down in a short time and become unusable. You will also be relaxed because you know that you will get a replacement very easily. Consider the scope of your work, if you do a lot, it means that it is more likely to fail.

Then it is especially important to think about the warranty. Of course, it is necessary to examine the small print of the system warranties. This way you will know how quickly your machine will be repaired and ready for use again. In addition, you will have other important information such as cost. You will get this information if you talk to a salesperson who is obliged to provide it to you if it exists.

Conclusion

You need to be careful when buying a laser cutter. This purchase will not be cheap, so it is important to consider several factors that affect its final outcome. If you check the functions of the machine, future costs, warranty and similar things in advance, almost nothing will be able to surprise you. It’s a way to insure yourself and work even better on your projects.